3D printing

Production › 3D printing

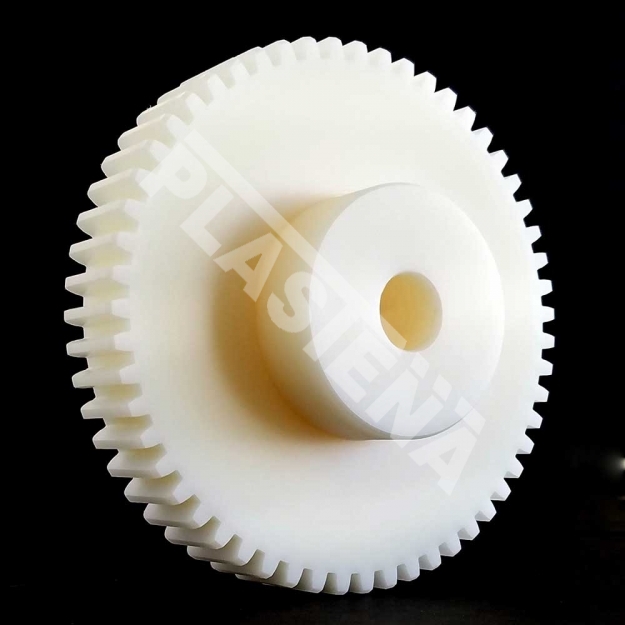

3D printing or additive manufacturing is the process of making a three-dimensional solid object of almost any shape from a digital model. FDM is the most common 3D printing process, commonly used to create ultra-small details. Such printing is achieved using an additive process where layers are stacked in different shapes (using a sequential layering technique). This type of manufacture is attractive for materializing products of complex geometry because, unlike milling, it provides unlimited freedom of geometric complexity of the model.

Depending on your idea and criteria for the product, we will choose the most suitable type of plastic from a wide selection. For 3D printing we use: ABS, PET, PA, PC, PPA, TPU plastics.

Features:

- We produce one-piece parts up to 600x600x600 mm. The smallest part or its part size is 2 mm

- 0.06 mm minimum print layer

- Maximum printable angle that does not require load-bearing structures and is achieved good surface quality - 45 o

- Tolerances (possible dimensional deviations) ± 0.5 %

Field of application:

- Unique plastic parts for an industrial equipment, building models and parts of broken items

- Manufacture of personal and business gifts

- Manufacture of prototypes

- Visualization of three-dimensional computer models

The 3D printing method stands out due to its production deadlines and attractive prices. It is most suitable for printing small series and unitary orders, as printing of a single part can take several hours.